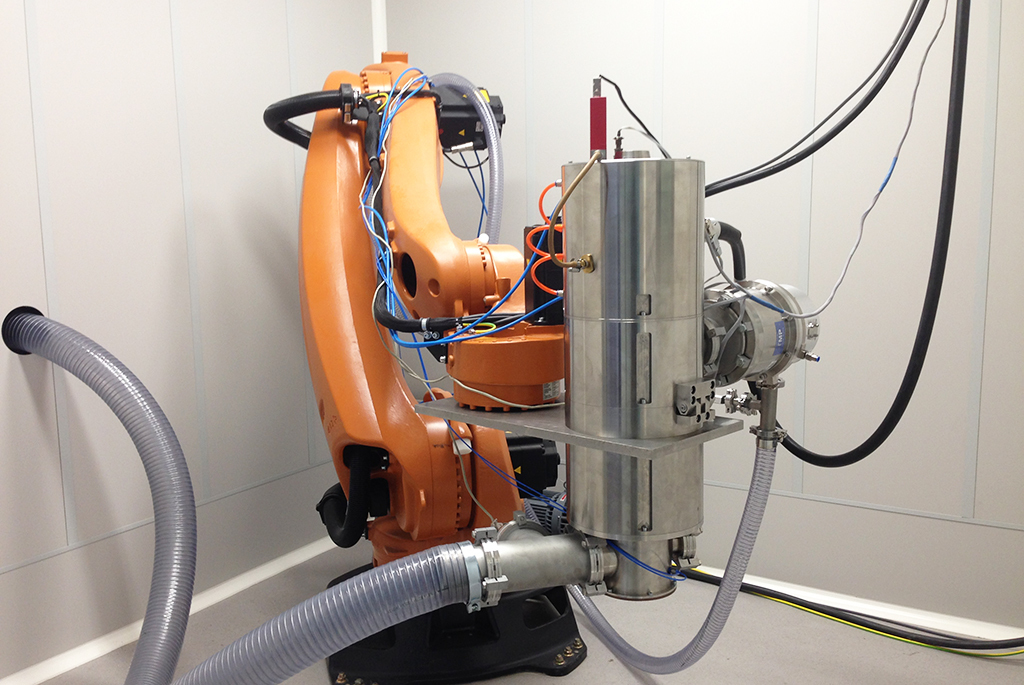

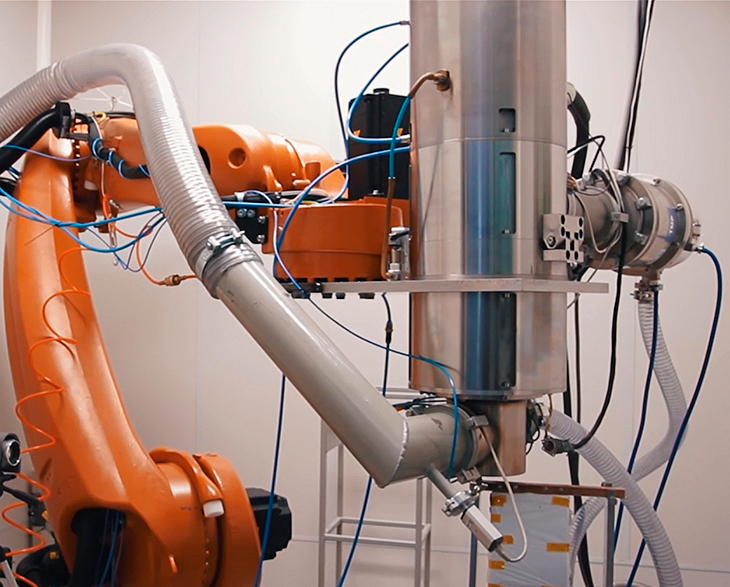

Non-vacuum Electron-Beam Plasma-Emitter System

Description

The focused electron beam is a source of thermal power for thermal treatment of various materials. The majority of technologies rely on vacuum-based beam application. In certain cases, however, vacuum becomes an extremely expensive condition to create, e.g. in treatment of large machine parts. An alternative approach for such cases would be to apply a non-vacuum beam technology. Applied out of vacuum, the electron beam can be used for metals welding and cutting, metal surface coating and other purposes.

Most non-vacuum electron-beam devices make used of a hot-cathode gun. The hot cathode is placed in high vacuum and the beam is extracted to the atmosphere through a differential pumping system. Such beam extractor systems are structurally complex and expensive.

The new focused beam extractor with a plasma emission gun constitutes a simple, power-efficient and highly competitive industrial equipment. Reliable operation is achieved in a lower initial vacuum than required for hot-cathode guns.

Specifications

- Operation: continuous.

- Electron emitter type: plasma.

- Max accelerating voltage: 120 kV.

- Max beam current: 200 mA.

- Beam focusing: electromagnetic.

- Type of beam extraction system: gas-dynamic pump.

- Number of pumping stages: 2.

- Pressure difference: 0.0005 to 760 mm Hg.

- Min transmission efficiency: 80%.

- Atmospheric transport distance: 1 cm min.

Advantages

A plasma-cathode electron gun has no hot electrodes, which allows it the following advantages: low cathode sensitivity to metallic and gas discharge from the operational area; longer life; a simple beam extraction system.

Application

Machine building, aircraft engineering, nuclear industry, metals industry, other industries that involve metals and alloys.