Intelligent Thermosabilizing Coatings

Description

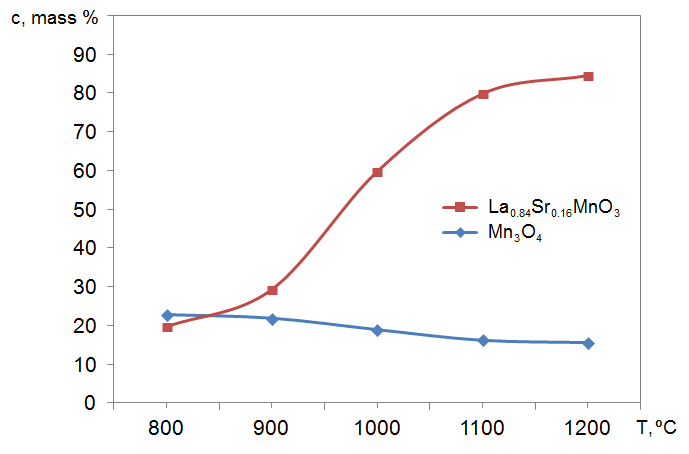

The new intelligent thermostabilizing coatings are formed by detonation layering or by application of paint made of barium titanate zirconate powder and rare-earth metal manganite with controllable phase transition and high resistance to radiation.

When subject to change of external energy conditions (temperature, input power, incoming radiation) these coatings can automatically (passively) control the thermal flux emitted by the coated objects and maintain their temperature. Temperature stabilization is achieved due to change of the crystal structure from dielectric to quasi metallic, and emissivity over a wide range within the phase transition range of BaTi(1-x) Zrx и La(1-х)SrхMnO3.

These coatings can be produced as paints or as 50—300 micron layers, detonation-applied to the metal substrate.

Specifications

- Emissivity variation range: 0.35 – 0.75

- Operating temperature rang: – 50 ° С to + 80 ° С

-

Integrated absorption coefficient:

- 0.35 –0.37 (detonation coating),

- 0.25 – 0.28 (paint coating)

-

Changes in the integrated absorption coefficient after 10 years: for the low earth orbit:

- 0.07–0.09 (detonation coating) for barium titanate coatings, and 0.02 – 0.03 for managinte and rare-earth element coatings

- 0,15 – 0,17 (paint coating),

-

for the geostationary orbit:

- 0.14 – 0.16 (detonation coating) for barium titanate coatings,

- and 0.05 – 0.07 for managinte and rare-earth element coatings 0.24 – 0.26 (paint coating)

Advantages

These coatings can ensure a wide range of control of heat emission and maintain specific temperature of coated objects.

The coatings have a high resistance to radiation and high level of adhesion to the metal base.

Application

The coatings can be used for:

Temperature regulation in spacecraft, reactors used in chemical, nuclear and other industries.

Efficient use of energy in residential buildings and industrial facilities.

Zr(%D1%85)O3_%D0%BE%D1%82_%D0%BA%D0%BE%D0%BD%D1%86%D0%B5%D1%82%D1%80%D0%B0%D1%86%D0%B8%D0%B8_%D0%B7%D0%B0%D0%BC%D0%B5%D1%89%D0%B0%D1%8E%D1%89%D0%B5%D0%B3%D0%BE_%D1%8D%D0%BB%D0%B5%D0%BC%D0%B5%D0%BD%D1%82%D0%B0_.png?1524133453)